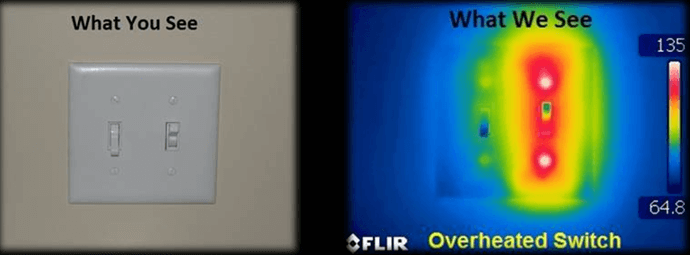

Infrared Scanning

As part of our testing capabilities, we use infrared scanning to inspect electrical equipment. Usually heat is the first sign of trouble with equipment. Loose connections, imbalanced or overloaded circuits, defective circuit breakers, damaged switches, faulty fuses, and material defects all lead to equipment failure.

Our technicians are Level 2 IR Certified.

Infrared Inspections

Avoid These:

- Emergency Repairs

- Lost Revenue

- Excessive Downtime

- Hazardous Conditions

- Catastrophic Failures

- Fire and/or Death

While Gaining These:

- Confidence in Electrical Reliability

- Improved Safety

- Improved Equipment Life & Performance

- Reduced Repair Costs

- Reduced Downtime

- Increase Tenant Satisfaction

- Return on Investment

How much does unexpected downtime affect revenue, safety, and customer satisfaction?

Cost of failure – A planned shutdown for maintaining equipment is significantly less expensive than a “run to failure” maintenance program.

Unexpected Downtime and Losses – One of the worst situations for clients and building management,

which can rack up losses in revenue quickly.

Reliability – Problems can be anticipated and repaired before a catastrophic failure.

Prevent fire and safety hazards – Give clients and faculty peace of mind with their building.

Insurance – Most insurance companies require an infrared inspection periodically and may offer discounts for certain preventative maintenance plans in place.

Non-destructive testing – Infrared testing does not require equipment to be shut down.

Switch Gear Maintenance

- An infrared inspection does not negate the need for periodic switchgear maintenance.

- The National Fire Protection Association standard for performing periodic maintenance of switchgears range from every 3 months to six years depending on system critical and environmental conditions.

- A solid maintenance program has been shown to be less costly than a switchgear failure; which usually will result in destruction of property, injury or death, loss of work time, costly cleanup, and replacement of expensive switchgear.

- The average Main Service Switchgear is custom built. A catastrophic failure could take months

of costly down time to replace.

| Thermographer | SPINELLA | |

|---|---|---|

| Requires an electrician | X | |

| Uses other contractors for repairs | X | |

| Has Electrical License | ✔ | |

| Allowed to open equipment covers | ✔ | |

| Can tighten most loose connections during testing | ✔ | |

| Tests for overloads on hot breakers | ✔ | |

| Perform safety inspection | ✔ | |

| Cite code violations | ✔ | |

| Can repair problems | ✔ | |

| Switchgear Maintenance | ✔ |

Companies who currently use our annual infrared inspection services: